Butter Solutions

Efficient butter processing solutions engineered for high-volume production with consistent texture, precision portioning, and hygienic packaging. Ideal for commercial butter manufacturing operations.

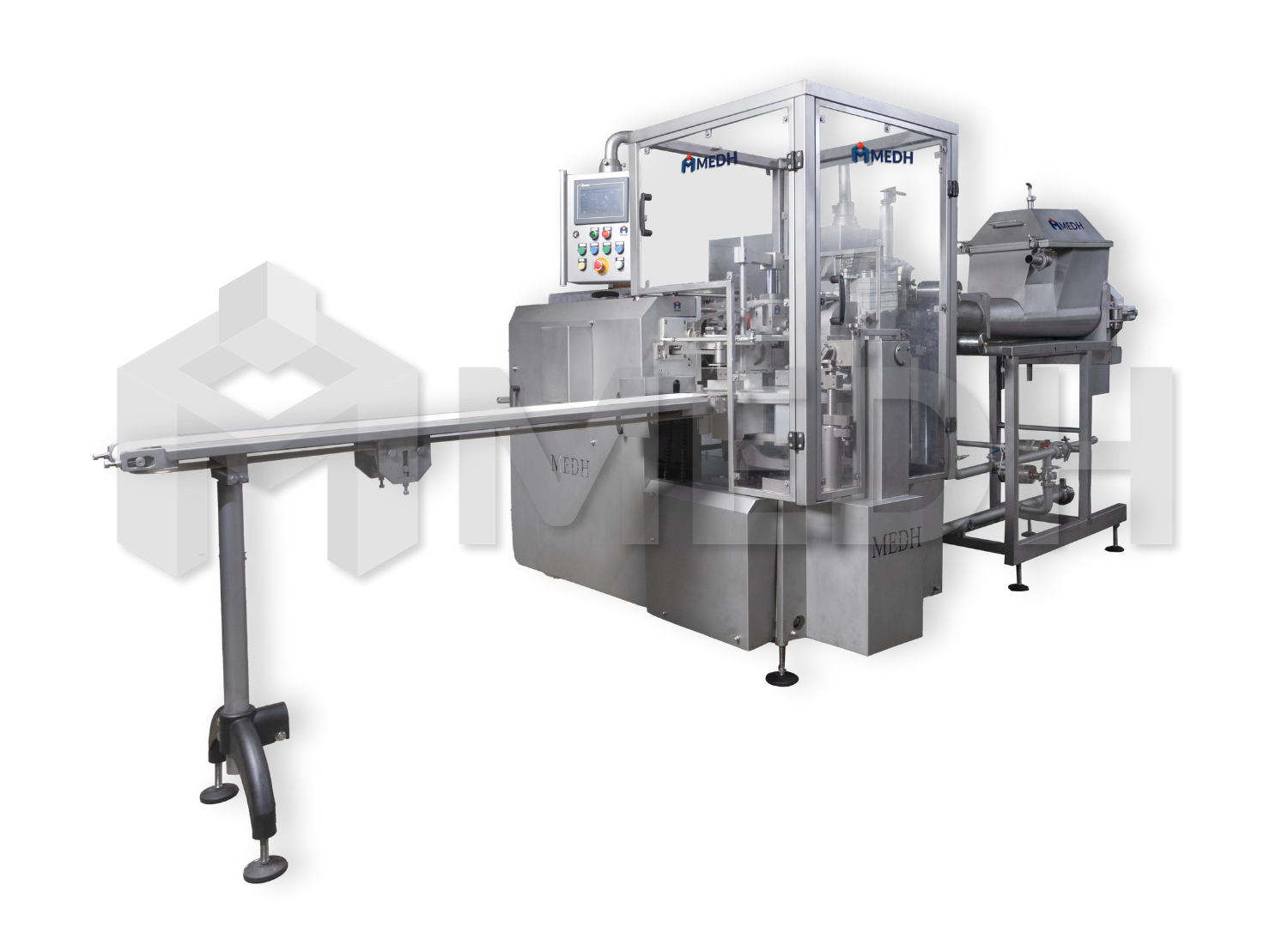

Automatic Butter Wrapping Machine

Our advanced Butter Wrapping Machine is engineered to deliver precision filling and high-speed wrapping of butter in 100g to 500g packs using roll-form wrapping material. Featuring proprietary technology for 100-500g, this single machine handles everything from accurate dosing, block forming, to tight, hygienic wrapping, ensuring consistent pack quality and extended shelf life.

Build-to-order Machine Variants & their Production Capacity on a single machine

Robust 25: 10 - 25g portions

Robust 250: 100 - 250g butter bricks

Robust 500: 250 - 500g butter bricks

Flex 1000: 100 - 500g butter bricks

Flex 2000: 500 - 1000g butter bricks

An integrated CIP system ensures consistent, automated cleaning for dairy equipment, improving hygiene and reducing downtime. It also lowers labor and resource costs while supporting regulatory compliance and product safety.

Built for modern dairy processing plants, the machine supports continuous, automated operation with minimal human intervention. The integrated Auto CIP (Clean-in-Place) system ensures complete sanitation of product-contact areas, meeting stringent hygiene standards and reducing downtime.

Designed to work seamlessly with aluminum foil, parchment paper, or laminated film, this machine is ideal for both retail and bulk packaging. Whether you're packaging table butter or white butter, it delivers unmatched performance in terms of speed, reliability, and pack consistency.

Perfect for dairy plants, cooperatives, and private labels, this butter wrapping solution offers a future-ready platform for cost-effective, high-quality packaging.

Key Features:

Fills and wraps butter sticks on the machine as per customer requirements

Works with roll-fed wrapping materials

Patented forming and wrapping technology

Auto CIP system for hygiene and easy maintenance

Compact design with high output efficiency

Butter & Cheese Grinder Machines for Frozen Block Grinding [at 18º C]

Our Butter and Cheese Grinder Machines are robust, industrial-grade solutions designed to grind frozen dairy blocks — including butter, processed cheese, and natural cheese — at temperatures as low as -18°C. These machines effortlessly convert hard, frozen blocks into small pieces, ready for further processing or mixing.

Powered by heavy-duty motors and equipped with high-torque cutting blades, these grinders are built to handle tough, frozen textures without compromising performance or hygiene. Ideal for use in butter reprocessing, ghee making (melting butter), cheese blending, or food ingredient preparation, they reduce manual labor and increase productivity in your processing line.

Key Features:

Handles frozen blocks of butter or cheese down to -18°C

Produces smaller particle sizes for further processing

Built with food-grade stainless steel and easy-to-clean components

Designed for continuous operation in demanding production environments

Safe, efficient, and compliant with dairy and food industry standards

Whether you're looking to pre-process bulk butter for re-blending or break down cheese blocks for melting, mixing, or packaging, our grinder machines offer the speed, power, and reliability needed in today’s high-volume dairy facilities